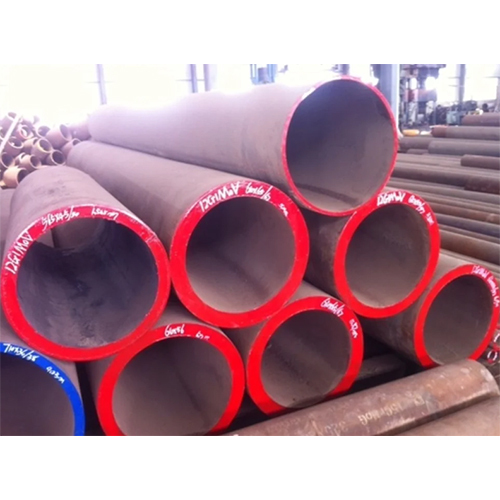

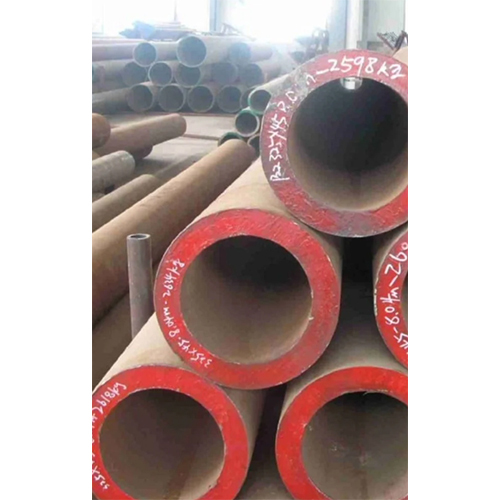

A335 Astm Gr P11 Pipe Smls Pipe

160.0 INR/Kilograms

Product Details:

- Product Type Seamless Steel Tubes

- Application Hydraulic Pipe, Oil Pipe, Chemical Fertilizer Pipe, Boiler Pipe, Gas Pipe

- End Protector Metal Pipe Cap

- Tolerance 1 Micrometers (um)

- Surface Finish Mirror Polish

- Material Carbon Steel

- Section Shape Round

- Click to View more

X

A335 Astm Gr P11 Pipe Smls Pipe Price And Quantity

- 160.0 INR/Kilograms

- 1 Kilograms

A335 Astm Gr P11 Pipe Smls Pipe Product Specifications

- DIN

- Mirror Polish

- 1 Micrometers (um)

- Metal Pipe Cap

- 1

- 6 Meter (m)

- Seamless Steel Tubes

- 168 Micrometers (um)

- 6

- Is Alloy

- Carbon Steel

- Hydraulic Pipe, Oil Pipe, Chemical Fertilizer Pipe, Boiler Pipe, Gas Pipe

- Round

A335 Astm Gr P11 Pipe Smls Pipe Trade Information

- 1 Week

Product Description

ASTM A335 Grade P11 is a seamless ferritic alloy steel pipe designed for high-temperature service, featuring chromium (1.00-1.50%) and molybdenum (0.44-0.65%) for enhanced strength, creep resistance, and oxidation resistance, making it ideal for power generation, petrochemicals, and oil & gas, with good weldability and formability for high-pressure, high-heat applications.

Key Characteristics:

- Type: Seamless (hot-rolled or cold-drawn).

- Material: Ferritic Alloy Steel (Chrome Moly).

- Key Alloying Elements: Chromium (Cr) and Molybdenum (Mo).

- Primary Use: High-temperature, high-pressure environments.

Chemical Composition (Typical):

- Carbon (C): 0.05 - 0.15%

- Manganese (Mn): 0.30 - 0.60%

- Phosphorus (P): Max 0.025%

- Sulfur (S): Max 0.025%

- Silicon (Si): 0.50 - 1.00%

- Chromium (Cr): 1.00 - 1.50%

- Molybdenum (Mo): 0.44 - 0.65%

- Tensile Strength (Min): 415 MPa (60 ksi)

- Yield Strength (Min): 205 MPa (30 ksi)

- Elongation (Min): 30% (Longitudinal), 20% (Transverse)

- Power plants

- Refineries

- Petrochemical plants

- Oil field services

- Boilers, superheaters, heat exchangers

- Excellent high-temperature strength.

- Superior creep and oxidation resistance.

- Good weldability, bendability, and flangability.

- High toughness and wear resistance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese